Environmental impacts of disposable cups and reusable cups

By Steffen Andersen · 13. August 2019

There has over the years been an increasing and much-needed discussion on the environmental friendliness of disposable cups. We are in this blog post going to compare paper cups, reusable plastic cups, and ceramics cups to see their individual effect on the environment, and which circumstances each cup is best suited for.

We are primarily going to focus on the energy used to create each type of the cups, and how many re-uses are needed for a reusable cup to have a per-use energy consumption lower than a disposable cup. We will end the discussion with a deeper look into how the lifecycle of cups influences their environmental friendliness.

To write this blogpost I have done a lot of research and found some different sources that I will present during the post. You can see all the links at the end of the post.

How are the different cups made?

The ceramic cups are largely made by heated clay. Clay comes from the ground and is normally mined near streams and rivers. The clay is then transported to production facilities for the ceramic cups. The clay needs to be mixed with several products such as quartz, feldspar and water. Further in the process the clay will be molded and formed to the cup form and then heated several times (depending on which mug you want). The heating process requires a lot of energy. (Ref.)

Reusable plastic cups are often made from polypropylene plastic (PP). The plastic is primarily made of naphtha oil which is made by a fraction of raw oil. These fractions are made during the refining process of oil where it is split into fractions of naphtha, hydrogen and other carbons. The plastic is then created in a process called polymerization and during this, monomers such as ethylene and propylene are linked together to form polymer chains, which the plastic eventually is made of. The plastic used for reusable plastic is thermoplastic, which is the definition of plastic that softens on heating and hardens again on cooling (Ref). After that process, the plastic is transported to a facility who will form the thermoplastic into plastic cups by injection molding.

Paper cups are made from wood chips. The chips are turned into wood pulp, which is then mashed into the paper. Afterward, a thin layer of PLA or PE plastic is applied to make the paper waterproof. The coated paper is then transported to manufacturers who might print on the paper and thereafter fold the paper into a cup shape and inserting the bottom.

What does the research say?

Now let’s try to compare the different cups to each other. We will do it by the help of professor named Martin B. Hocking who analyzed the energy use of disposable and reusable cups back in 1994 (Ref). This is the latest research we could find in the area.

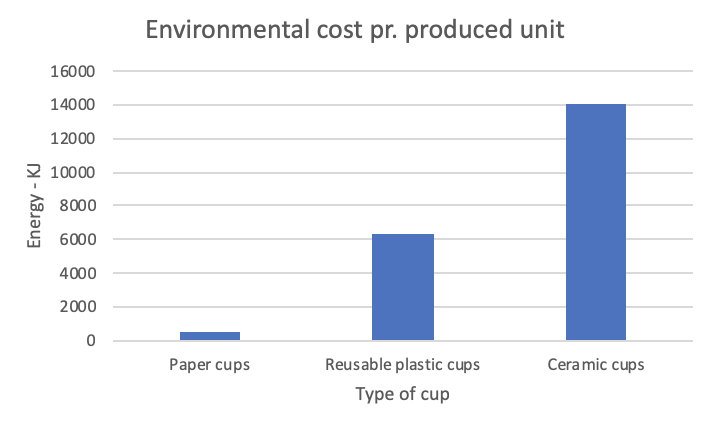

A ceramic cup requires 14.1MJ (14.100 KJ) per cup to manufacture. A reusable plastic cup takes 6.3 MJ (6.300 kj) to manufacture. A paper cup takes 0.5 MJ (500 KJ) to manufacture. As we already can see the reusable cups uses much more energy in the production. In other words, at very best, a plastic cup needs to be used 12 times to be as efficient as a paper cup. A ceramic coffee mug would require 28 uses compared to a paper cup.

Then let’s add the energy of washing. In Martin B. Hocking indicates a commercial washier requires between 80 and 120 KJ of to wash a single cup amongst an entire wash load. The reason for the high emission of KJ washing a single cup is due to the energy used when heating up the water and cooling it down again so quickly. A commercial washer has a wash cycle, a rinse cycle, and heats the water to a scalding 80 degrees C. (Ref)

You should take into consideration that the analysis was made in 1994 and we did not have the most efficient commercial dishwashers. This still doesn’t mean that commercial dishwashers don’t uses a large amount of energy washing. It means that the energy used can vary from machine to machine.

Besides taking washing into consideration, we will need to consider the difference between the energy used, and energy expended at power plants to produce the energy used by the dishwasher. The efficiency of power plants differs from country to country and from energy source to energy source. But if we use Germany as an example they have 6 main sources of energy. (Ref) The average power plant in Germany will deliver 60 % of the energy from the fuel it burns, this is with taking renewable energy into consideration. We have to divide the wash energy by 0.60 getting a higher number of energy burnt to wash reusable cups. Dividing the 80 KJ of energy of a dishwasher by 0.60 results in 133 KJ to wash a cup.

Which gives another result than mentioned earlier, a reusable plastic cup needs to be used at least 17 times to be as efficient as a paper cup and a ceramic cup need to be used 38 times to be as efficient.

The used values for each technology are the best available at the market, which means the KJ can wary a lot if the manufacturing facility is inefficient. We need also to take into consideration that the values used is from the Martin B. Hocking analysis which is made in 1994 and somethings have changed since then.

How about the Life-cycle of the cups?

The energy expenditure of disposables and reusable cups do also vary depending on the way they are either recycled or used for biomass as an energy source.

A discarded ceramic cup has no recycled value, but it will, if recycled correctly, be crushed and then used to make insulation and other materials. If plastic cups are sent to plastic recycling and if paper cups are sent to incinerators rather than landfill they have what is called a recoverable energy benefit. Meaning they can be reused to create new plastic or burnt to create heat or electricity and thereby decrease the need for other energy sources like oil or coal. The reusable plastic cups have recoverable energy of 2364 KJ for each cup which amounts to a little more than 1/3 of the manufacturing cost. The paper cups have recoverable energy of 166 KJ for each cup which 1/3 of the manufacturing cost.

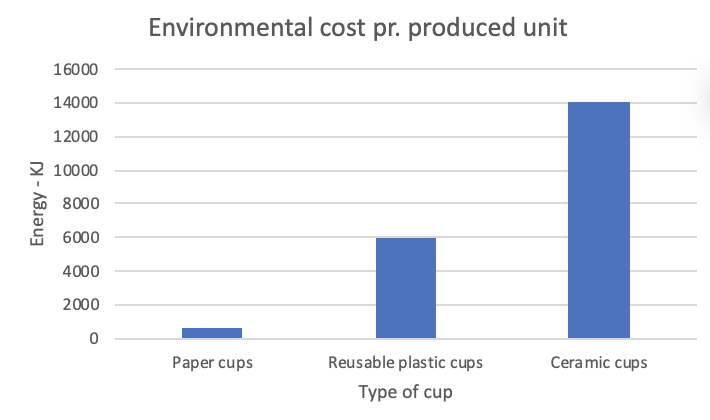

Subtracting the recoverable energy usage we end up with an energy spend of 3936 KJ/cup for a recyclable plastic cup and 383 KJ/cup for paper cups. The ceramic cup will stay the same. Which gives the following use of energy in the life-cycle of the cups.

Collection of plastic in recycling operations has been estimated to have energy costs of 0.28-0.40 kj/g and 26.7 kj/g.(Ref) Here we assume that there is a similar energy cost to recycle paper. This equation, of course, depends on the weight of individual cups. A standard reusable plastic cup weighs 75.4 g/cup and our paper cups weigh 9.34 g/cup. To add up the numbers the net energy of producing, using and recycling the cups, the reusable plastic cup will then use 5971 kj and the paper cups will then use 635 kj during the life cycle. But we should of course only recycle the cups where the energy costs can be kept low. In some countries such as Denmark, they do not recycle the paper cups both because they don’t have the systems to recycle them, but also because they use paper cups for biofuel which is categorized as a renewable energy source. Which gives the following use of energy in the life-cycle of the cups.

Conclusion

The numbers of times a reusable cups needs to be used depends on the energy cost in production, transportation and how the cups are disposed of. All the alternatives wary from country to country. But even though some guidelines would be that the disposable cups fit best for the situation where you should only use the cup a couple of times and it will be disposed of after that. Where the reusable cups are more fit for office buildings and home where they will be used several times.

If you have any questions, comments or other things feel free to write to me on [email protected] or call me on +45 30 69 21 89. I will always be happy to help you with finding more information or other inquiries.